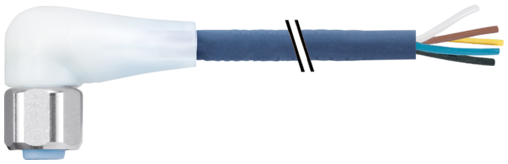

M12 female 90° A-cod. with cable LED F&B Pro

TPE-S 5x0.34 bu UL robot+drag ch. 7.5m

| Art. nr.: | 7024-12441-3390750 |

| Vægt: | 0.276 kg |

| Country of origin: | DE |

Kontakt os for leveringsdato

Beskrivelse

Plug Connectors for Food & Beverage

Further cable lengths on request.

Female 90°

M12 F&B Pro

5-pole

Stainless steel 1.4404 (V4A)

without cable sleeves

IP69K

Plastic housings with good resistance against chemicals and oils.

The resistance to aggressive media should be individually tested for your application. Further details on request.

Tekniske specifikationer

| Cable length | 7,5 m |

|---|

Side 1

| Tightening torque | 0,6 Nm |

|---|---|

| Mounting method | inserted, screwed |

| Coating contact | gold plated |

| Family construction form | M12 |

| Thread | M12 x 1 |

| Coding | A |

| Material contact | Copper alloy |

| No. of poles | 5 |

| Width across flats | SW14 |

| Degree of protection (EN IEC 60529) | IP65, IP68, IP69K |

Side 2

| Stripping length (jacket) | 20 mm |

|---|---|

| Coating contact | gold plated |

Electrical data | Supply

| Operating voltage DC | 24 V |

|---|---|

| Operating voltage DC min. | 18 V |

| Operating voltage DC max. | 30 V |

| Current operating per contact max. | 4 A |

Diagnostics

| Status indication LED | green, white, yellow |

|---|

Installation | Connection

| Stripping length (jacket) | 20 mm |

|---|

Device protection | Electrical

| Additional condition protection degree | inserted, screwed |

|---|---|

| Pollution Degree | 3 |

| Rated surge voltage | 0,8 kV |

| Material group (IEC 60664-1) | I |

Mechanical data

| Contour for corrugated hose | without |

|---|

Mechanical data | Material data

| Color contact carrier | ice blue |

|---|---|

| Material gasket | EPDM |

| Material housing | PP |

| Material contact carrier | PP |

| Locking material | Stainless steel 1.4404 (V4A) |

Mechanical data | Mounting data

| Mounting method | inserted, screwed, Shaking protection |

|---|

Environmental characteristics | Climatic

| Operating temperature min. | -40 °C |

|---|---|

| Operating temperature max. | 85 °C |

| Additional condition temperature range | depending on cable quality |

Important installation notes

| Note on strain relief | Protect the connectors by suitable measures from mechanical loads, e.g. by the usage of cable ties. |

|---|---|

| Note on bending radius | Attention: Observe the permissible bending radii when laying cables, as the IP protection class can be endangered by excessive bending forces. |

Conformity

| Product standard | DIN EN 61076-2-101 (M12), FDA conform |

|---|

Kabeldata

General data | Cable

| Cable identification | 339 |

|---|---|

| Jacket Color | blue |

Structure | Cable

| Amount stranding | 1 |

|---|---|

| Stranding | 5 wires around Core filler twisted |

| wire arrangement | brown, black, blue, white, green-yellow |

Mechanical data | Cable

| Cable weigth | 35,2 g/m |

|---|---|

| Material jacket | TPE-S |

| Shore hardness jacket | 47 ± 5 Shore D |

| Freedom from ingredients (jacket) | lead-free, cadmium-free, CFC-free, halogen-free, silicone-free |

| Outer-diameter (jacket) | 5 mm |

| Tolerance outer diameter (sheath) | ± 5 % |

| Material wire insulation | PP |

| Amount wires | 5 |

| Outer diameter insulation | 1,27 mm |

| Outer diameter tolerance core insulation | ± 5 % |

| Shore hardness wire insulation | 64 ± 3 Shore D |

| Ingredient freeness wire insulation | lead-free, cadmium-free, CFC-free, halogen-free, silicone-free |

| Amount strands (wire) | 42 |

| Diameter of single wires | 0,1 mm |

| Conductor crosssection (wire) | 0,34 mm² |

| Material conductor wire | Stranded copper wire, bare |

| Conductor type (wire) | strand class 6 |

| Traversing distance (C-track) | 10 m @ 25 °C | horizontal |

Electrical data | Cable

| Nominal voltage AC max. | 300 V |

|---|---|

| Current load capacity (standard) | to DIN VDE 0298-4 |

| Current load capacity min. wire | 4,5 A |

| Electrical resistance line constant wire | 58 Ω/km @ 20 °C |

| AC withstand voltage (wire - wire) | 3 kV @ 60 s |

Temperature range | Cable

| Min. operating temperature (static) | -40 °C |

|---|---|

| Max. operating temperature (fixed) | 105 °C |

| Operating temperature min. (dynamic) | -25 °C |

| Operating temperature max. (dynamic) | 105 °C |

Resistances | Cable

| Flame resistance | UL 1581 § 1100 FT2 | IEC 60332-2-2 | UL 1581 § 1090 |

|---|---|

| chemical resistance | Good, application-related testing |

| Gasoline resistance | Good, application-related testing |

| Oil resistance | DIN EN 60811-404 | Good, application-related testing |

Installation | Cable

| Bending radius (fixed) | 5 x Outer diameter |

|---|---|

| Bending radius (dynamic) | 10 x Outer diameter |

| No. of bending cycles (C-track) | 4 Mio. @ 25 °C |

| No. of torsion cycles | 2 Mio. |

| Torsion speed | 35 cycles/min |

| Torsion stress | ± 180 °/m |

Commercial data

| ECLASS-6.0 | 27279218 |

|---|---|

| ECLASS-6.1 | 27279218 |

| ECLASS-7.0 | 27279218 |

| ECLASS-8.0 | 27279218 |

| ECLASS-9.0 | 27060311 |

| ECLASS-10.1 | 27060311 |

| ECLASS-11.1 | 27060311 |

| ECLASS-12.0 | 27060311 |

| ETIM-5.0 | EC001855 |

| customs tariff number | 85444290 |

| GTIN | 4048879752213 |

| Pakke-enhed | 1 |

Tilbehør

---- Sensor-aktuator adapter ----